Assessment of a construction technique for load-bearing walls

A building system for load-bearing walls combines insulating panels that are fitted with electro-welded reinforcement meshes on which shotcrete is projected on both sides. Separately, all components are regulated by harmonized regulations, but the whole kit does not fall within the field of application of any EN standard. ITeC has verified that the proposed system matches the terms of the EAD 340002 and has overseen the process towards a European Technical Assessment.

Technical-regulatory advice and guidance for future certification of a façade system

A team of developers is working on a new building system for façades, and they need to know how it fits into the regulations. ITeC has analyzed the proposal vis-à-vis the existing European standards (and their possible future evolutions) and has outlined the roadmap (objectives, technical requirements, methodologies, etc.) that should be followed during the final development of the system for a smooth market entry from a legal perspective.

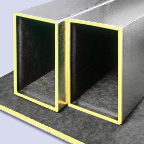

Evaluation of HVAC ducts built with mineral wool boards

The EN standards that regulate mineral wool do not cover the case of HVAC ducts built with this kind of boards, so they can not be CE-marked. An EAD document has been developed, enabling the possibility for this type of ducts to get a CE mark if they are backed by an ETA that substantiates their satisfactory thermal performance, safety in case of fire, acoustic behaviour and durability, among others.

Environmental Product Declaration for a range of synthetic insulation products

Obtaining an Environmental Product Declaration (EPD) is a two-step process, implementation and verification, which must be entrusted to a EPD consultant. In the case of this family of insulation products, the implementation has been entrusted to ITeC as an authorized consultant for the DAPcons® system. The process begins with a Life Cycle Analysis (LCA) with the Simapro® software and the latest version of the Ecoinvent database, obtaining also the carbon footprint. The verification is carried out by another consultant, external to ITeC, who reviews the reports, the calculation method and the results obtained.

Window calculator tool

The purpose of this tool is to promote the benefits of replacing old windows with new ones with better insulating properties. The user is asked to input the climatic zone where the building is located and the solar orientation of each window, and then is guided towards the most adequate choice of window, including the cost of the frame and glass, as well as the potential savings that can be achieved both in terms of energy (kWh/year) and money (€). The tool is designed to be updated according to the price fluctuations of energy and the components of the window.

Homeskin project: development of high-performance insulation materials

Homeskin is a project within the European Horizon 2020 program, and its goal is the development of new products and building solutions for thermal insulation based on AABC composites, which have an aerogel content that can achieve 3 times more efficiency than standard insulation products. ITeC's has monitored how these new products fit within the European building standards so that they can enter the market as smoothly as possible.

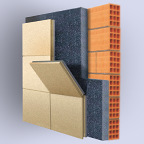

EAD for the evaluation of Veture façade systems

The so-called “Veture systems” are façade building systems with the same purpose as ETICs, but they are always mechanically fixed to the supporting wall. Originally, CE marking of these kits followed the criteria of ETAG 017 until the European Construction Products Regulation (EU 305/2011) required that they be regulated by a European Assessment Document (EAD). ITeC has collaborated with the Center Scientifique et Technique du Bâtiment (CSTB) to draft the EAD that will be used as a reference by all EU Technical Assessment Bodies to evaluate Veture kits.

Life Reusing Posidònia project: low environmental impact vegetal insulation

Life Reusing Positronia is an EU-funded project that involves the construction of a building to demonstrate the feasibility of producing dwellings with a very small environmental footprint. It tests building systems where thermal and acoustic insulation is provided by dried marine plants that are collected on a beach near the site. ITeC has contributed to the calculations of energy consumption and CO2 emissions derived from the building materials chosen.

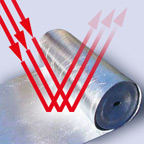

Evaluation of reflective insulation products

The measurement of the thermal insulation performance of these products is substantially different from the methods used for traditional products, since their behaviour depends not only on the conduction and convection inside their mass, but above all on the refection on their surface. In addition, their placement on site is also different from that of the traditional solutions and it conditions deeply the effectiveness of the insulation.

Assessment of amorphous thermal insulation techniques solutions for cavity walls

The manufacturer of a system for inserting a thermal insulation material into cavity walls can declare the performance of their products, but this largely depends on a proper execution process. This assessment document describes best practices for pre-application checks, required equipment, drilling pattern definition, injection sequence, and final quality checks.